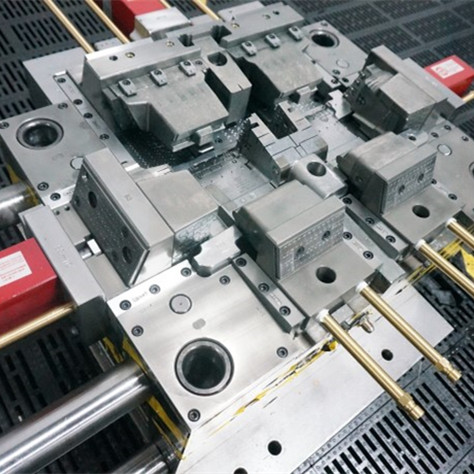

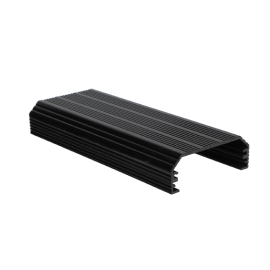

Pvc Glossy

Profile Plastic

It can be divided into two types based on performance: hard and soft.

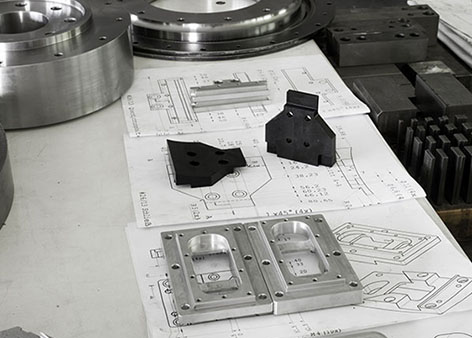

Acrylic

co-extruded profiles

Provide transparent color, customized color, sand surface, etc

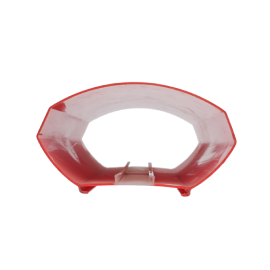

Extruded curved

corner profile

ABS plastic is not afraid of water or moisture, making it more durable than traditional wood.